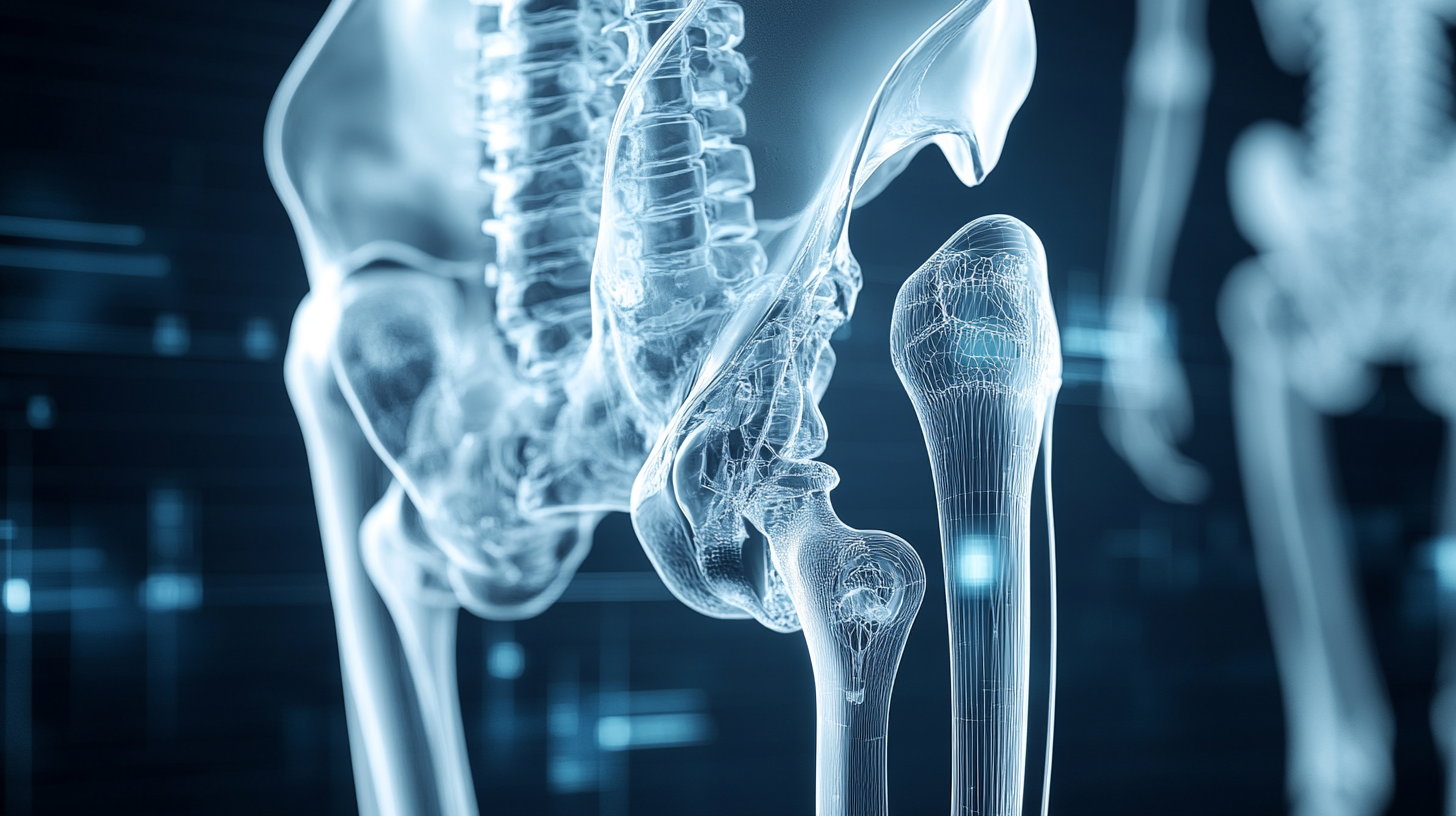

The requirement for hip joint implants is on the rise due to the aging population and increasing cases of hip disorders. As per a report by Grand View Research, the hip implant clinical market globally would stand at USD 9.1 billion by 2025, representing a 3.2% compound annual growth rate. Such growth in the market further underlines the need for high-quality implants from reliable suppliers, as the efficacy of these medical devices directly influences the outcome and recovery for the patient. Therefore, supply of good products, keeping up with standards, is arguably the most important for the orthopedic care of patients.

The maze of hip joint implants can be confusing thanks to all the choices flooding the marketplace. Armed with a strong understanding of all top manufacturers with their product lines and conformance standards in the industry, one can procure with success. As stated by the Orthopedic Research Society reports, however, quality in hip joint implants is not merely regulatory. It is intrinsically connected to the forefront of innovation and technology associated with the field. The scope of this handbook is to offer assistance to buyers searching for quality suppliers in terms of making well-informed decisions that will eventually benefit medical professionals and their patients.

Besides identifying defining qualities of reliable suppliers of hip joint implants, it is also important to consider whether such suppliers have a good track record in meeting the industry's standards and regulations so that consumers can be sure that the products they offer would pass strict safety and performance criteria. They are more than mere compliance with the standards; one would look out for certifications from suppliers that would tell of better management systems and manufacturing processes. This resembles the recent stability in the equestrian sales market in terms of their strong customer confidence, which further highlights the having of trust among suppliers. Check what kind of technological advancements and innovations are being introduced by the supplier into their manufacturing processes. It will be mostly with vendors concerned about research and development that you are going to get the much-needed cutting-edge implant technologies that will improve patient outputs. The high-flying eCommerce in the present day as seen in the recent investment rounds raising funds for startups in relevant fields entails that all suppliers should learn about new technologies. The quality suppliers in the orthopedic implant market would use world-class manufacturing tools and methods that would distinguish them from their competition. Excellent customer service and aftersales service form the other important feature of excellent suppliers. Long-term partnerships with suppliers who show responsiveness and collaboration can make the difference to any medical practice or institution. Just as buyers see value in the extensive support available in the collectible market, so should the medical professional and institution value suppliers who provide more than just products, offering up a way for processes to run more smoothly and patient care to be improved. Holistic assessment of suppliers would be inclined to yield wise decisions which subsequently improve clinical outcomes.

Most important in the context of hip joint implants is the selection and qualification of good suppliers. The supplier certification and standard against which the qualification occurs represents a critical consideration. Certification reflects the supplier's commitment to quality, and at the same time, certification assures the healthcare practitioner that the products are safe and efficacious.

International regulations defining the conduct of suppliers for the medical device industry include ISO 13485 and FDA's Good Manufacturing Practices (GMP). ISO 13485 assures that a supplier creates a quality management system to assure its clients that any products meet their requirements and the requirements of local statutes and regulations. GMP applies to relatively few aspects of medical device manufacture and testing, mainly ensuring product manufacture minimal risk. These certifications let buyers know that they are dealing with suppliers determined to meet quality and compliance standards.

Finally, industry standards promulgated by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) should also be considered. Conformance to these standards will typically lead to improved access to markets and also shows a supplier's ability to innovate while ensuring safety. For buyers, an understanding of these certifications and standards not only allows for informed decision-making when buying but also enables any quality assurance work related to the hip implant supply chain.

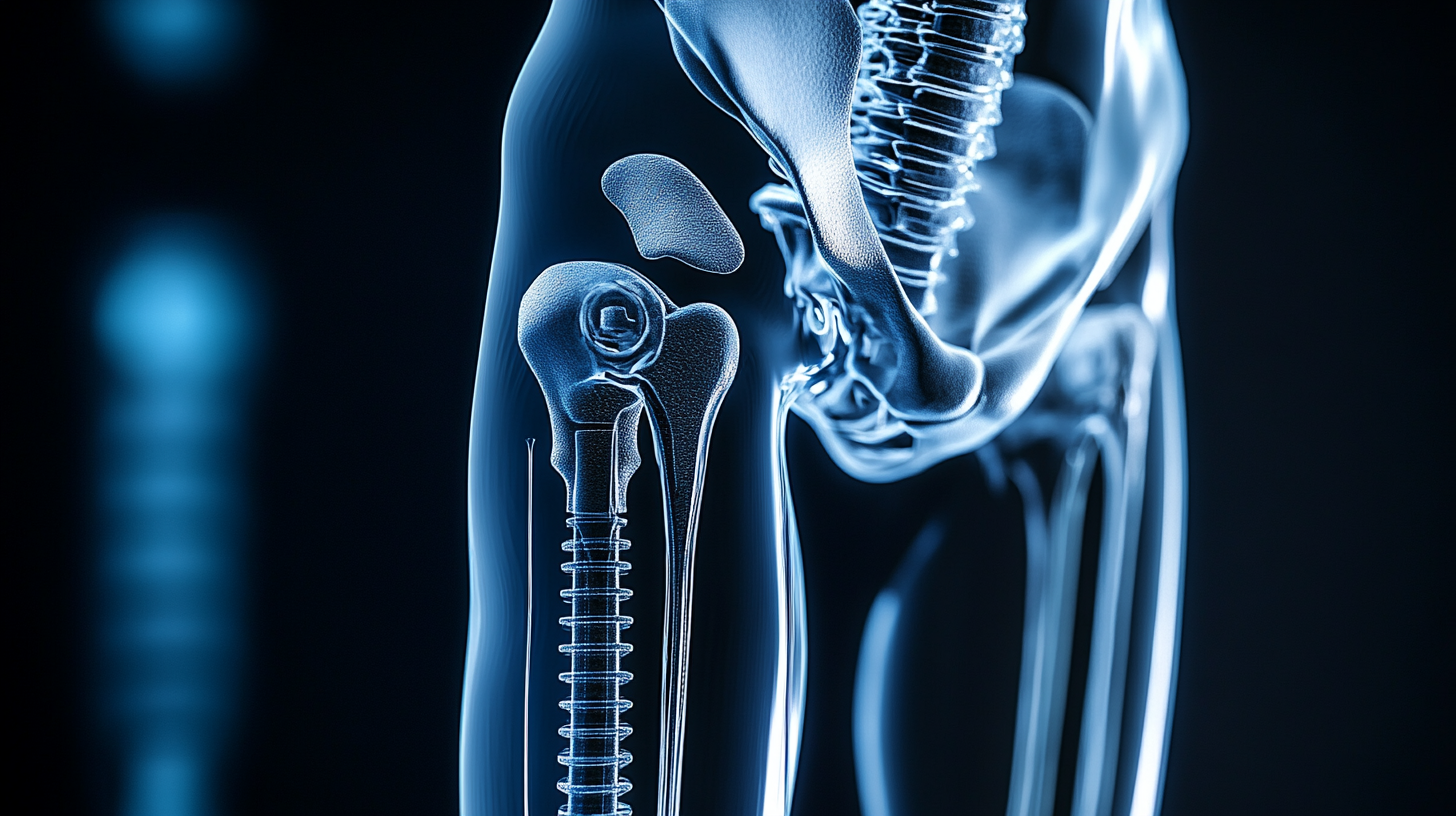

It is more important than ever that both patients and their surgeons truly understand exactly what materials and technologies are involved in their hip joint implants. The type of materials used in implants impacts their durability, biocompatibility, and overall performance. This naturally includes titanium alloys with their proven strength and impeccable corrosion resistance, the member of polymer composites known for providing flexibility and shock absorption. All these materials have their inherent advantages as well as limitations which have to be weighed against each other in the search for the best-fit option.

Technology has an equally important role to play in the manufacture and design of artificial hip joints. It has evolved to the point where 3D printing and computer-aided design (CAD) have ushered in personalized, tailor-made implants for individual patient anatomy. These newest technologies not only add to the exactness of the placement of implants but also make it possible to have innovative developments that could improve the functionality of the joint and shorten recovery times. It prepares the buyer, together with all the technological advancements, to make a sound judgment concerning which suppliers incorporate the latest techniques in their implant production.

Eventually, an all-round assessment of the material used and the technology involved will bring about the course of supplication in the right supplier for hip joint implants. In a rapidly changing environment within the medical scene, improvement will face the adoption of such technologies and higher quality materials, which will lead to better fortunes for patients in need of hip joint replacement. This integration of such suppliers can go a long way toward achieving the best results by having those suppliers who constantly keep upgrading their offers with new research findings and trends.

It matters most to assess the reputation and customer feedback of a supplier when actualizes the decision of selecting suppliers for hip joint implants, especially in light of recent safety investigations conducted on these products. There are indeed reports suggesting "poisonous" hip replacements that have brought a huge nuisance physically and mentally to several scores of patients. Such revelations put an emphasis on scrutinizing suppliers on grounds of a history of adverse effects correlated to their implants.

Such would potential recalls highlight even more on the aspects of assessing supplier credibility. Recalls disclose product potential dangers, such as leaching harmful metals into the bloodstream, which pose substantial health hazards to patients. Preferably, the suppliers should be assessed by consumers on the basis of clear histories and certifications, as well as stringent testing to which the minimally satisfactory safety record is to be compared.

Reviews are one of the best tools in this selection process. Testimonials may act as guides when one designs one's expectation from a past patient experience who has used the implants and the support given by the suppliers. By balancing regulatory information with user feedback, buyers make informed decisions that reduce the risk associated with hip joint implants, thereby improving outcomes for patients.

In the competitive environment of orthopedic implants, after-sales support and warranty are two major deciding factors for buyers. Recent developments in the orthopedic industry, especially at Zimmer Biomet, show that these are more than just contractual obligations; they are very important for creating durable ties between manufacturers and healthcare providers. The presence of the necessary after-sales support ensures that healthcare professionals are able to tend to the problems challenging optimal recovery rates for patients in a timely fashion. The warranty offers confidence, signaling the manufacturer's confidence in its products.

After-sales assistance feeds further trust and satisfaction into the already rich mutual relationship between a surgeon and an implant supplier. As demonstrated in New Zealand, the business uses surgical implants in extreme stages of development; this is a living case in point to express how a strong after-sales service creates an opportunity for novel technology. Trust is built through customer service, and this heightens the experience of users: medical personnel willingness as well as patients. While overseas states join the fray, with the recent domestic joint implant approved for use in the U.S., attention to after-service care becomes even more pivotal. An efficient after-sales service will make the difference for suppliers in this prospective market, a factor that buyers need to mulling over when choosing their partners.

Suppliers should have certifications such as ISO 13485 and adhere to the FDA’s Good Manufacturing Practices (GMP) to ensure quality and compliance with safety standards.

Evaluating supplier certifications is crucial because they indicate the supplier's commitment to quality and assure healthcare providers that the products meet stringent safety and efficacy requirements.

Industry standards set by organizations such as ANSI and ISO help ensure that suppliers maintain safety protocols, innovate effectively, and gain better market access.

Common materials include titanium alloys, known for strength and corrosion resistance, and polymer composites, which provide flexibility and shock absorption.

Technologies like 3D printing and computer-aided design (CAD) enable personalized solutions, improve implant precision, and allow for innovative designs that enhance functionality and recovery times.

Material quality affects the longevity, biocompatibility, and overall performance of the implants, making it crucial to choose materials that best fit individual patient needs.

Advances in technology can improve the precision of implant placements and lead to better designs, resulting in improved joint functionality and reduced recovery times for patients.

Buyers should seek suppliers who use the latest technologies and regularly update their offerings based on the most current research and advancements in the field.

Understanding certifications helps buyers make informed decisions, ensuring they engage suppliers who prioritize product quality and regulatory compliance.

A comprehensive evaluation of suppliers, based on certifications, materials, and technology, enhances the quality assurance process by ensuring better selection of reliable and innovative suppliers.